What is a lean supply chain ?

"Lean supply is often viewed as one of a set of techniques for managing operations effectively (Found and Rich, 2007)"

A lean supply chain describes how an excellently-designed supply chain will work, delivering goods to the end user efficiently, with minimal waste. A lean supply chain is a great facilitator for any organization, which seeks to become leaner and more reliable.A structured approach to developing and maintaining their supply chain will help companies aspiring to become lean.

Why do we need a lean supply chain?

Increase profits

Enforcing a lean supply chain will cut down on unnecessary procedures, storage requirements, and waste. Besides the increased revenue that this could bring to your company, it can also improve your profits.

Reduce waste

If you try to make the supply chain as effective as possible it can eliminate waste. Waste must be disposed of which includes processes and studies, as well as transportation.

Streamline your processes

Processes will become complex as supply chain grows too. Often such innovations will carry inefficiencies with them, inherit now-defunct measures, and create duplication. All of which result in time being spent where they are not required at the cost of being spent in places that might produce greater results for the investment.

Customer satisfaction

Erasing pointless stages in the supply chain puts your goods into the hands of your clients much quicker, enhancing their satisfaction with your firm and boosting their possibility of becoming loyal customers. consumers are more likely to suggest the company to their peers, relatives or colleagues, thus increasing their sales .

How to get a lean supply chain?

Eliminate All Waste

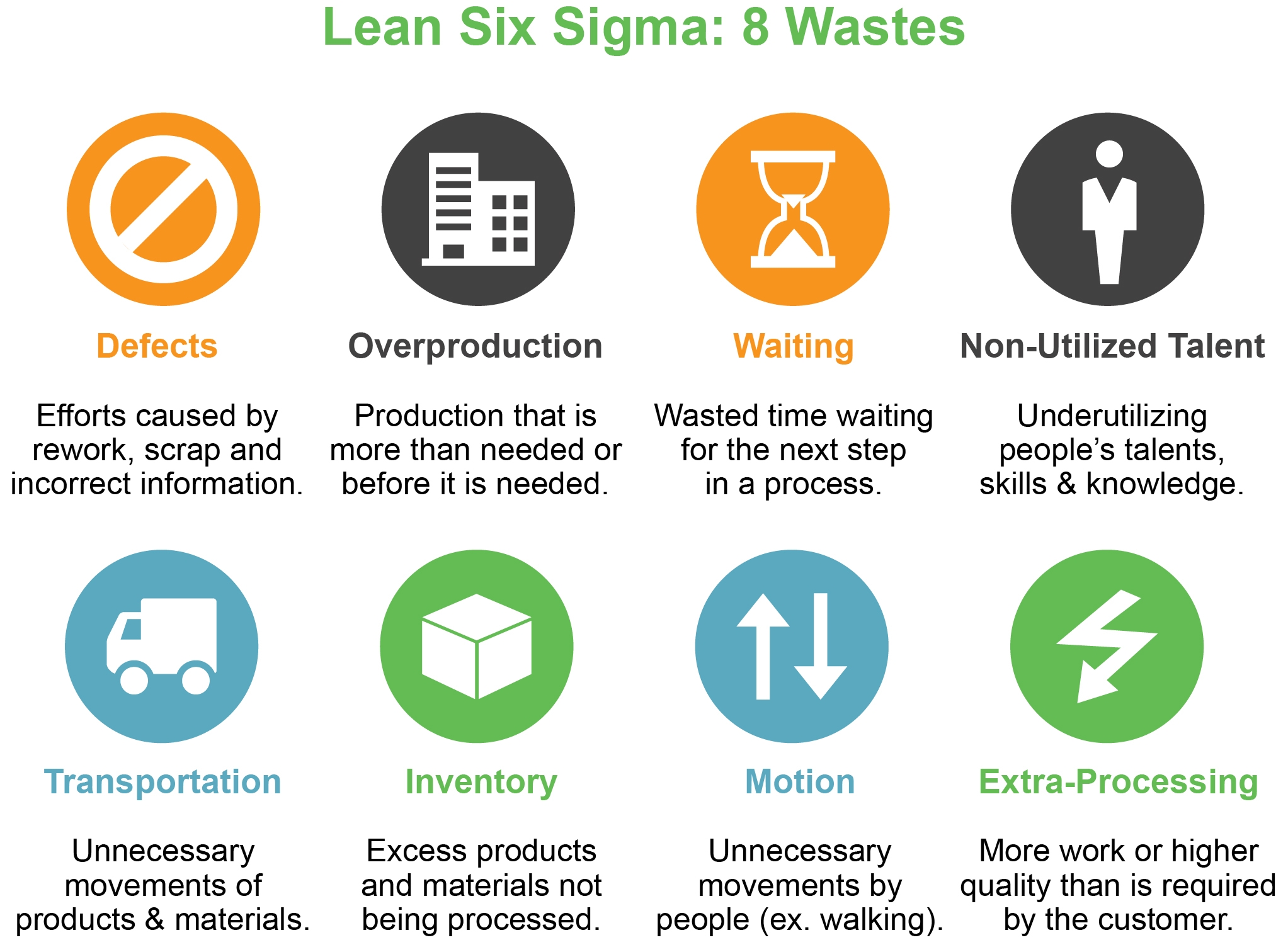

The firm should remove all non value adding activities. There are 8 wastes that needs to eliminated. (1) Defects, (2) Overproduction, (3) Waiting, (4) Unused Talent,(5) Transportation,(6) Inventory, (7) Motion, (8) Extra processing

Advancements in Technology

Firm should consider advancements in technology such as Supply Chain Management (SCM) systems,Trading Partners Interface,Omni-channel fulfillment, GPS for tracking freight, transportation management system, workforce management throughout the Supply Chain etc.

Lead Time Reduction

Logistics reduction takes one closer to consumer demand, resulting in decreased forecasting dependency, increased efficiency and reduced overproduction waste. Working in collaboration with suppliers or customers helps reduce lead times and increase customer value.

Create a Level Flow

Creating a material and information flow results in a lean supply chain at all key points of the network, with far less waste.

Use Pull Systems

A pull method is a Lean technique for reducing any production process waste. The implementation of a pull method helps you to launch new work only when the client wants it. example Kanban system reduce wasteful complexity in planning and overproduction that can occur with computer-based software programs such as Enterprise resource planning ERP.

Concentrate on cost of Completion

Decide things that satisfy customer requirements at the least total cost possible , regardless of where they occur along the supply chain. This means eliminating judgements that only benefit one part of the stream to the detriment of others.

Reduce Variation, Increase velocity and throughput time

Satisfying consumer demand by delivering smaller shipments improves efficiency and throughput to your customers more often . This, in effect, helps to minimize inventories and lead times and enables you to more quickly tailor distribution to meet real customer needs.

Sure, there is a cartload of benefits your business gets with a lean supply chain. What do you think is the major value that your customers will get when your supply chain gets leaner? Can you get specific about, "Customer satisfaction"?

ReplyDeleteThis comment has been removed by the author.

DeleteThere will be reduced lead time , hence customers get what they want at a faster rate increasing their satisfaction and fill rate. This is achieved while lowering cost, hence this can be pointed out over various other advantages, shall share part 2 of this blog. stay tuned. Thank you for showing interest in this topic, will keep you posted

DeleteWould a supply chain being more technologically advanced (automation, AI, ML) have an advantage over tranditional lean supply chain or will it be the opposite ??

ReplyDeleteThat is an interesting question, shall be addressed in my part 2 of my blog, please stay tuned . But i shall tell you this, both have their own advantage and drawbacks, its your firms strategic goals and capabilities that decide whats best for you.

ReplyDelete