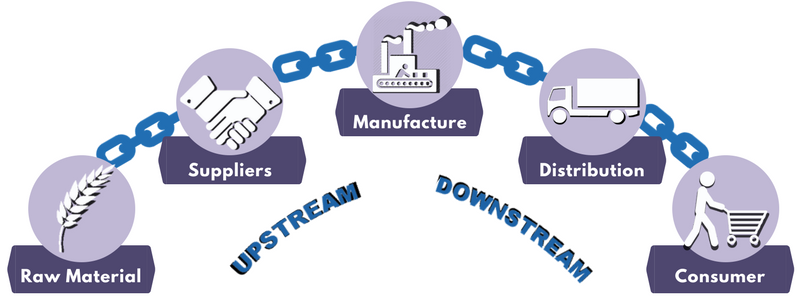

Supply chains consist of all the measures involved in bringing a product into customer's hands from raw material. The supply chain usually begins with the manufacturers or retailers. Manufacturing is the next step in the supply chain. It is the method of transforming the raw materials into ready for sale items. The last step is delivery that can include many intermediaries.

Some of those intermediaries might be

Wholesalers,

Retailers,

Distributors,

E-commerce and the Internet (Influencers).

The different stages within the supply chain are called upstream and downstream.

Upstream processes are the ones where the products flow into the organization.

Downstream operations are those in which materials flow away from the organization to the customers (mostly in the form of finished products).

Likewise, the word logistics is used when thinking about the supply chain of a company.

Inbound logistics are linked to the upstream operations which involve all the component movement before fabrication. We include obtaining products, processing them, and the procedures needed to produce the product.

Outbound logistics are related to downstream operations involving just about all of the product's movement once it is a finished good.

While we're frequently linked with the supply chain on the basis of terms, what about procurement and sourcing? Typically these two terms are used interchangeably with supply chain when, in fact, each refers to a completely separate role in a supply chain involved. You may think of sourcing as part of the manufacturing process, as they form part of a supply chain together.

The goal of procurement is to identify the selection of various vendors for the goods. Research and negotiation are a normal part of this process because a company's profitability can rely heavily on material costs.

Depending on how a business decides to compete with the market, what will ultimately support that decision is its supply chain. The supply chain consists of different systems that work to produce a commodity, these systems pave the foundations for a business choosing to add value. What gives a business a competitive advantage over others, is the value chain. The more demand that is generated, the more a buyer needs a good, and therefore the greater the profit that a business generates.

The different approaches focus on bringing consumer service within multiple levels of the supply chain. He describes supply chain functions that include, distribution, inbound processes, outbound logistics, marketing and advertising, and support. We already know that inbound logistics and outbound logistics are part of the supply chain we defined as being. Operations are more or less a different term for manufacturing since they are all activities involved in turning raw materials into a product.

educative

ReplyDelete