Logistics in F1

Formula 1 is the pinnacle of the

racing sport with its high-speed cars, innovative technology and a well

collaborative team. A win in F1 can be due to the performance of the car,

driver, the strategy used, weather and luck. But the most important factor is

the performance of the car since even gain in a microsecond can decide between

the first position and second position. The car used in F1 is equipment with

crucial components and instruments. Usually, the calendar of F1 starts from March

to December covering 21 Grand Prix over 5 continents with 1-2 weeks apart after

each Grand Prix and around 1-month vacation after 12th Grand Prix in August. A

Grand Prix starts is a 3-day event starting from Friday with 2 practice

session, 3rd practice session and qualification on Saturday and Race on Sunday.

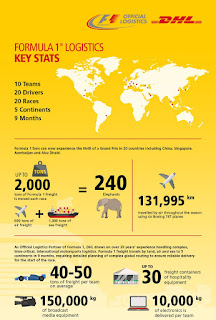

F1 2019 consisted of 10 teams and each team has two drivers i.e., two cars. F1 is not just racing, for these teams, it is also business. These teams are worth over billions of US dollars which are expected to make money from the races. All of the teams are operated in Europe which is a good thing as most of the Grand Prix are held in Europe.

Teams use

different logistics mode to reach their destination. Teams need to transport

cars, components, spare parts, equipment including the electronic instruments

and buildings for which they use trucks, ships or flights. Currently, DHL is

the official logistics partner of Formula 1.

The cost of shipping by truck is so comparatively low to shipping by plane that teams bring whole buildings with them to the European races. These buildings are what are modestly referred to as “motorhomes” but can be as large as a three-story structure that includes offices, bars, and a restaurant with a complete kitchen. All of that packs into several trucks and can be assembled in less than two days. Along with all the other equipment including cars, spare parts, and electronics, convoys of dozens of trucks per team criss-cross the continent before each European race.

Typically

races are held every two weekends on Sunday which gives teams plenty of time to

relocate before the activity begins on the Thursday before the Grand Prix but

from time to time the schedule is crunched and races take place two weekends in

a row. This proves a logistical challenge as teams only have three full days to

break down, transport, and reassemble their equipment at the new race site.

But, these races are easy

logistically compared to the ones outside of Europe. These races are known as

flyaway races. Just like with the European races the majority of flyaway races

occur with two weeks between them but from time to time races are scheduled on

back to back weekends thousands of miles apart. These back to back flyaway

races are the most logistically difficult weeks of Formula 1. They send these

bulkier and less expensive pieces of equipment by sea as it’s massively less

expensive than sending them by plane. The number of containers per team varies

as the wealthier teams will take more but in general, each team takes about

three 40 foot containers. Of course, ocean shipping is slower, but since there

are five sets there is always one at the right place at the right time.

At the racetrack, the Formula 1 logistics team’s main downtime is actually during the race itself but for the transfer real work begin on Thursday before the race. That’s when each team’s logistics manager started making their tear-down plan, deciding in which order and into which containers their different pieces of equipment should go. Once that is completed there is not a lot to do until Sunday. On Sunday morning, before the race even started, the pack up begins. Many of the spare parts can’t be used during the race, also they’re not going to replace an engine during the Grand Prix, so they’re the first pieces of kit to be packed into their containers.

The cars, the most important pieces of equipment, are subjected to a post-race inspection to be sure no illegal modifications are made but everything else is immediately ready for packing. All the equipment that the teams want at the destination first is put in one of three priority pallets. Together each team’s priority pallets fill up the first plane. As soon as these are packed they are driven directly to the airport only a few hours after the race ends to be prepared for an early morning flight. As that plane takes off the final pallets are packed up back at the racetrack. Only about six to eight hours after the drop of the checkered flag, all pallets are packed up and on their way to the airport. By midday, Monday, all six of the Boeing 747’s used to transport the team's equipment are in the air. These planes are chartered by Formula 1 but the teams still pay for space.

Also on Monday,

all the staff start their journey to the next race track. Many of the lower-level the staff just fly on normal commercial flights while some of the higher-profile

drivers fly privately between the two countries. After nine hours in the air,

the first plane touches down in the next destination around early evening local

time. The freight is unloaded and brought to customs. By midnight, all the

priority freight is on its way to the racetrack. Overnight, logistics workers

arrange the different teams’ freight into their respective paddocks.

No team is allowed to touch their freight until all the other teams’ freight has arrived both for fairness purposes and safety to assure that there aren’t many people around as pallets are being unloaded and moved. By Tuesday morning, it’s game on for the assembly crews. At this point, each team have their three priority pallets and their sea kit. In their priority pallets, teams don't put the highest value or most important cargo, they put the things they need to assemble first—the bare bones of their garage. That includes the wall panelling, the core of their electrical system, and the majority of the IT and communications equipment.

By Tuesday

evening the building is done and the track is once again made inaccessible to

the teams as the non-priority pallets are delivered overnight. Early Wednesday

morning around 6 am the teams arrived back at the track and begin work on the

final assembly of the garage. Only after about four hours, by late morning, all

the different team's garages are operational.

All in all, ten Formula 1 team successfully pack up, ship all their equipment around 4,000 miles when transporting from one continent to another, and reassemble their paddocks in 58 hours. Thanks to careful planning and practised workers, Formula 1 pulls off this impressive feat every year without a hitch.

Reference:

https://medium.com/speedbox-is-typing/the-logistics-behind-f1-7537e445de20

https://f1destinations.com/the-logistics-of-formula-1/

Super interesting. Never wondered how. Thanks for raising the curtain on the topic :)

ReplyDelete